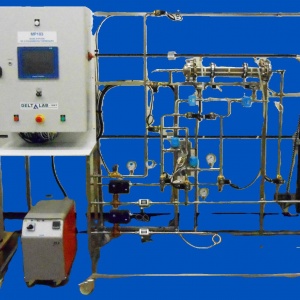

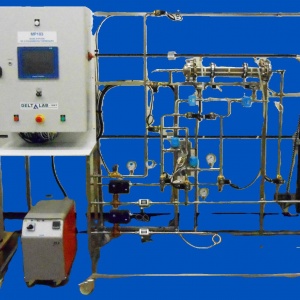

Non contractual photo

Service : 400 V - three phase, 50 Hz - 9 kW; Cold water 2 bar, 3 m3 / h

1 group of water heaters 9 KW, with pump and tank, water 95 ° C

Sewer

Dimensions : about 1700 X 850 X 2000 mm

Weight : 150kg

Print / download the product sheet

Print / download the product sheetThis bench allows the study and the comparison of 3 types of exchangers :

- Monotubular / coaxial (0.1 or ~ 0.2 m2)

- With plates (0.1 or ~ 0.2 m2)

- Multitubular (0.1 or ~ 0.2 m2)

The direction of flow can be reversed, allowing the study of co-current and countercurrent heat exchangers.

Experimental possibilities

Determination :

- Thermal balances

- Global exchange coefficients

- Flow regimes

- Influence of the hot fluid supply and cold fluid.

- Comparison of the efficiency of 3 types of exchangers.

- Establishment of different temperature profiles, calculation of average temperature differences.

- 1 monotubular / coaxial exchanger made of stainless steel

- 1 brazed plate heat exchanger

- 1 multitubular exchanger: consisting of a tube bundle whose one end is welded to a plate. The tubes are mounted inside a stainless steel or glass grille.

- The exchangers are made of stainless steel

- Manual valves in stainless steel for the selection of circuits.

- Pressure gauges

-1 float flowmeter (cold circuit)

-1 float flowmeter (hot circuit)

- Valve in stainless steel for adjusting the flow rates of cold and hot water circuits.

-12 Pt100 temperature probes

-Electric cabinet with 3-position switch for the selection of the type of exchangers, 1 switch 2 positions for the choice of the circulation mode (co or countercurrent),

- 6 temperature displays, with transmitters and emergency stop.

- The hydraulic circuit is made of stainless steel, mounted on a welded stainless steel frame.

-Technical manual

Option 1 (Data Acquisition): Two electromagnetic emittances replace the fuseholders.

The acquisition and the visualization of the temperatures and flows on makes a touch screen of 7 '', moreover these data can be transferred towards a computer (not provided) .The developed software makes it possible to display the temperatures according to the exchanger and the selected traffic mode. This software allows the acquisition and the recording of the measured values, the calculations and the plots of the heat exchange curves as a function of the time for each exchanger.

The following curves can be plotted:

Variation in the amount of heat exchanged as a function of flow

Variation in thermal efficiency E as a function of flow

Variation of heat exchange coefficient U as a function of flow

A synoptic of the installation is displayed on the screen, as well as the details of each exchanger.

An ergonomic menu allows to select the display of the different temperature and flow parameters according to the exchanger to be studied

Option 2 (supervision): This option allows the flow control of hot and cold circuits from a computer. Two flow rates are controlled by a stainless steel pneumatic valve, supplied with 2 P / I converters, the two converters are mounted in the control cabinet, and are configurable according to the computer.

Option 3 (water heating group): electric heating of 9 KW, with pump and tank, maximum temperature of 95 ° C.

Print / download the product sheet

Print / download the product sheet